Khetho ea mokhoa oa ho daea le oa ho qetela o ipapisitse le mefuta e fapaneng, litlhaloso le litlhoko tsa sehlahisoa se felileng sa lesela, le ka aroloa ka kalafo ea pele,dyeing, khatiso, ka mor'a ho qeta joalo-joalo.

Phekolo ea pele

Likhoele tsa tlhaho li na le litšila, ts'ebetsong ea masela le ho eketsa slurry, oli le litšila tse silafetseng, ho ba teng ha litšila tsena, ha li sitise feela tsoelo-pele e ntle ea ho daea le ho qeta ho sebetsa, empa hape li ama ts'ebetso ea ho apara ea lesela.

Sepheo sa phekolo ea pele ke ho sebelisa ketso ea lik'hemik'hale le ea 'mele ho tlosa litšila holim'a lesela, ho etsa hore lesela le be tšoeu, le be bonolo, le be le permeability e ntle ho finyella litlhoko tsa ho nka, le ho fana ka lihlahisoa tse tšoanelehang tsa semi-products bakeng sa ho daea, ho hatisa le ho qeta.

K'hothone: ho lokisa lesela le tala, singeing, desizing, beling, bleaching, mercerizing. Polyester: ho lokisa lesela, ho hloekisoa (alkali ea metsi, joalo-joalo), preshrinking, ho boloka, ho fokotsa boima ba alkali (alkali ea metsi, joalo-joalo).

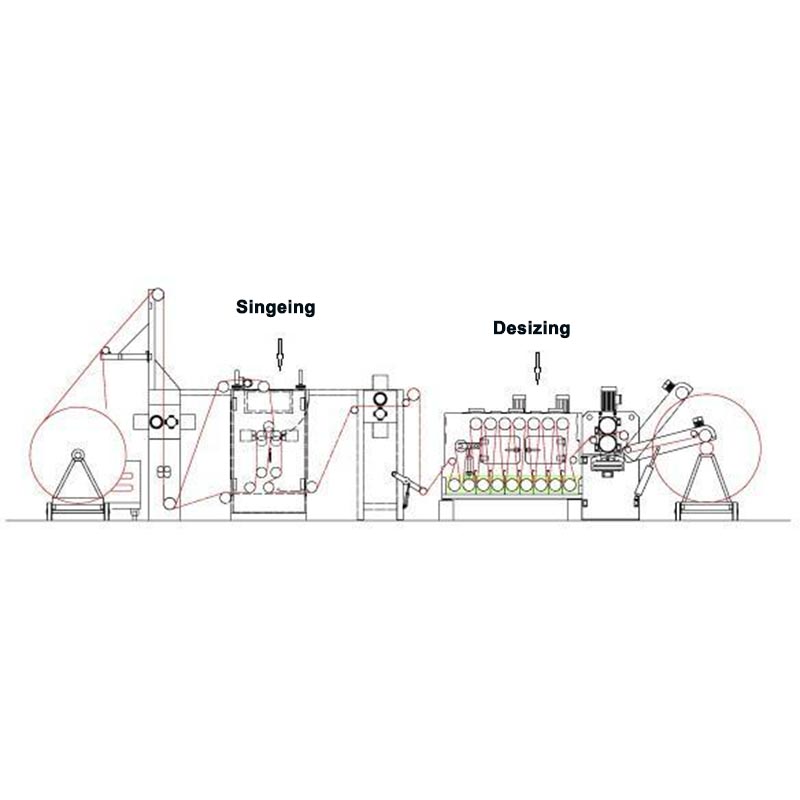

Ho bina

Hangata, ka mor'a ho kena fekthering ea khatiso le ho daea ho tloha femeng ea masela, lesela le leputsoa le lokela ho hlahlobjoa pele, le phetololoe, le beche, le hatisoe le ho roka, ebe lea binoa.

Mabaka:

(1) lesela le sa theoheleng fatše haholo, bolelele bo fapaneng;

(2) tekanyo ea ho qetela e fokola, e silafala habonolo;

(3) ka tatelano zhongyi boea ho daea le ho qeta, ho hatisa le ho daea liphoso.

Sepheo sa ho bina:

(1) ntlafatsa khanya ea masela; Ntlafatsa sephetho;

(2) ho ntlafatsa ho hanyetsa pilling (haholo-holo lesela la fiber ea lik'hemik'hale);

(3) ntlafatsa setaele, singeing ka etsa hore lesela e be crisp, ba ne ba lesapo.

Desizing

Ha ho lohuoa, sekoti se ba le tsitsipano e matla le likhohlano, tseo ho leng bonolo ho li khaola. E le ho fokotsa ho robeha ha warp, ho ntlafatsa bokhoni ba ho loha le boleng ba lesela le bohlooho, hoa hlokahala ho etsa boholo ba khoele ea warp pele o loha. Khoele e khoeleng e khomarela le ho tšoarana, 'me e etsa filimi e tiileng ea seretse holim'a khoele, e etsa hore khoele e tiee 'me e be boreleli, kahoo e ntlafatsa matla a ho robeha le ho hanyetsa ha khoele.

Morero oa ho etsa boholo: Ka mor'a ho lekana, seretse se phunyeletsa ka har'a likhoele 'me ka karolo e 'ngoe se khomarela holim'a sekoti. Ha e ntse e ntlafatsa ts'ebetso ea khoele, slurry e silafatsa mokelikeli oa ho daea le ho qeta ho sebetsa, e sitisa tšebelisano ea lik'hemik'hale pakeng tsa likhoele le ho daea le lisebelisoa tsa lik'hemik'hale, 'me e etsa hore ho be thata ho etsa dae le ho qeta ho sebetsa.

(1) Kenyelletso ea slurry e sebelisoang hangata

Slurry ea tlhaho: starch, seaweed gum, gum, joalo-joalo.

Lintho tsa starch:

① tabeng ea ho bola ha asiti;

② tabeng ea botsitso ba alkali, ho ruruha;

③ tabeng ea oxidants ka decomposed;

④ ka ho bola ha enzyme ea starch.

Chemical slurry: lintho tse tsoang ho cellulose tse kang hydroxymethylcellulose (CMC), joala ba polyvinyl (PVA), polyacrylic acid, polyester, joalo-joalo.

Lintho tsa PVA:

① e tsitsitseng ho acid le base, viscosity ha e fokotsehe;

② E senyeha ka lebaka la oxidant;

③ Ts'ebeliso e pharalletseng, e tsamaellana hantle, ha ho na karabelo e kopaneng

(2) Mekhoa e tloaelehileng e sebelisoang ho etsa desizing

1. Alkaline desizing

E 'ngoe ea mekhoa e sebelisoang ka ho fetisisa ho limela tsa ho daea malapeng, empa tekanyo ea desizing ha e phahame,' me litšila tse ling li ka tlosoa ha li ntse li cheka.

Mechanism: The tshebediso ya sodium hydroxide hlapolla tharollo kalafo, starch slurry tlas'a ketso ea alkali ho ruruha (kapa ho ruruha) phenomenon, ha ho etsahala lik'hemik'hale itšoara joang, e le hore slurry ho tloha gel ho sol, fokotsa matla a tlamang pakeng tsa faeba le slurry, 'me joale tšebeliso ea ho hlatsoa le mochine matla a ho e tlosa. Bakeng sa PVA le polyacrylate slurries, e khona ho qhaqha sodium hydroxide ka tharollo ea dilute.

(starch) desizing enzyme

Li-enzyme li boetse li bitsoa li-enzyme, li-biocatalysts.

Likarolo: sekhahla se phahameng sa deizing, eseng fiber ea kotsi, feela bakeng sa starch, ha e khone ho tlosa litšila.

Likarolo: a. Bokgoni bo phahameng. b. Lintlha tse tobileng: Enzyme e ka susumetsa karabelo e le 'ngoe feela kapa karabelo e itseng. c. Ts'ebetso e angoa ke mocheso le boleng ba PH.

Bakeng sa li-slurries tsa starch kapa li-slurries tse tsoakiloeng tsa starch (lintho tse ngata tsa starch li ka sehloohong), amylase e ka sebelisoa bakeng sa desizing.

Ho fokotseha ha acid

Kopo ea malapeng ha e ngata, hobane tšebeliso e bonolo ho senya fiber, e kopantsoe le mekhoa e meng. Mokhoa oa mehato e 'meli o amohetsoe: alkali desizing - acid deizing. Ho hlahisa asiti ho ka etsa hore starch e be hydrolyze, e tlose letsoai la diminerale joalo-joalo, 'me e etsane bakeng sa e mong..

Ho fokotseha ha oxidation

Moemeli oa oxidizing: NaBrO2 (sodium bromite) H2O2, Na2S2O8, (NH4) 2S2O8, joalo-joalo.

Molao-motheo: Mokelikeli oa oxidizing o ka oxidize le ho senya mefuta eohle ea slurry, boima ba molek'hule le viscosity e fokotsehile haholo, ho qhibiliha ha metsi hoa eketseha, 'me slurry e thibeloa ho khomarela fiber, ebe hydrolyzate e tlosoa ka ho hlatsoa hantle.

(1) Ho bela

Sepheo sa ho belisa ke ho tlosa litšila tsa fiber le ho ntlafatsa thepa ea ho sebetsa ea lesela, haholo-holo ho ba metsi.

Litšila tsa tlhaho: Bakeng sa masela a hloekileng a k'hothone, haholo-holo li-fiber co-organisms kapa lintho tse amanang le tsona, ho kenyeletsoa boka ba oli, pectin, protheine, molora, pigment le likhetla tsa cottonseed.

Litšila tsa Maiketsetso: litšila tse kang oli, antistatic agent le oli, mafome le seretse se setseng se kentsoeng mosebetsing oa ho ohla le oa ho loha.

Litšila tsena li ama haholo ho nosetsa ha lesela mme li sitisa ho daea le ho phethoa ha lesela, 'me li tlameha ho tlosoa tsamaisong ea scouring ka sodium hydroxide e le eona e ka sehloohong le li-surfactants e le thuso.

(2) Ho soeufala

Ka mor'a ho belisa, boholo ba litšila tsa tlhaho le tsa maiketsetso holeselali ntšoa, empa bakeng sa masela a soeufalitsoeng le a 'mala o bobebe, ho boetse hoa hlokahala. Ke ho tlosa pigment, ho ntlafatsa bosoeu e le morero o ka sehloohong oa ho etsa bleaching.

Lik'hemik'hale tsa lik'hemik'hale ha li na pigment, ka mor'a hore ho belisoa ho be tsoeu haholo, 'me fiber ea k'hothone ka mor'a ho hloekisa pigment e ntse e le teng, bosoeu bo bobe, kahoo bleaching ke haholo-holo bakeng sa litšila tsa tlhaho tsa fiber ea k'hothone.

(3) Bleach

Mofuta oa oxidation: sodium hypochlorite, hydrogen peroxide le sodium chlorite, joalo-joalo, e sebelisoang haholo ho fiber ea k'hothone le masela a kopantsoeng.

E fokotsehile: NaHSO3 le phofo ea inshorense, joalo-joalo, haholo-holo e sebelisetsoang masela a protheine fiber.

(4) Sodium hypochlorite bleaching:

Sodium hypochlorite bleaching e sebelisoa haholo bakeng sa ho soeufatsa masela a k'hothone le masela a kopantsoeng a k'hothone, 'me ka linako tse ling e boetse e sebelisetsoa ho soeufatsa masela a k'hothone a polyester. Leha ho le joalo, e ke ke ea sebelisoa bakeng sa bleaching fiber fibers tse kang silika le boea, hobane sodium hypochlorite e na le phello e senyang liprotheine, 'me e etsa hore likhoele li be mosehla le ho senya. Ts'ebetsong ea bleaching, ntle le ho timetsoa ha li-pigments tsa tlhaho, fiber ea k'hothone ka boeona e ka boela ea senyeha, ka hona, hoa hlokahala ho laola maemo a ts'ebetso ea bleaching, e le hore boleng ba ponahalo le boleng ba ka hare bo tšoanelehe.

Sodium hypochlorite e bonolo ho e etsa, e theko e tlaase, sodium hypochlorite bleaching operation e loketse, lisebelisoa tse bonolo, empa hobane sodium hypochlorite bleaching e mpe bakeng sa ts'ireletso ea tikoloho, kahoo butle-butle e nkeloa sebaka ke hydrogen peroxide.

(5) Ho soeufala ha hydrogen peroxide H2O2:

Hydrogen peroxide, eo hape e tsejoang e le hydrogen peroxide, e na le foromo ea limolek'hule H2O2. Ho soeufala ha hydrogen peroxide ho bitsoa bleaching ea oksijene. Ho tsitsa ha tharollo ea hydrogen peroxide ho futsanehile haholo tlas'a maemo a alkaline. Ka lebaka leo, hydrogen peroxide ea khoebo e fokola haholo.

Lesela le hloekisitsoeng ka hydrogen peroxide le na le bosoeu bo botle, 'mala o hloekileng,' me ha ho bonolo hore le be mosehla ha le bolokiloe. E sebelisoa haholo ho bleaching lesela la k'hothone. Ho hloekisoa ha oksijene ho na le ho ikamahanya le maemo ho feta chlorine bleaching, empa hydrogen peroxide e phahame ho feta theko ea sodium hypochlorite, 'me bleaching ea oksijene e hloka lisebelisoa tsa tšepe e sa hloekang, tšebeliso ea matla e kholoanyane, litšenyehelo li phahametse chlorine bleaching.

Hona joale, mokhoa o bulehileng oa ho soeufatsa mouoane o sebelisoa haholo lifemeng tsa khatiso le tsa ho daea. Mokhoa ona o na le tekanyo e phahameng ea ho tsoelapele, ho iketsetsa le ho hlahisa katleho, mokhoa o bonolo oa ho phalla 'me ha o hlahise tšilafalo ea tikoloho.

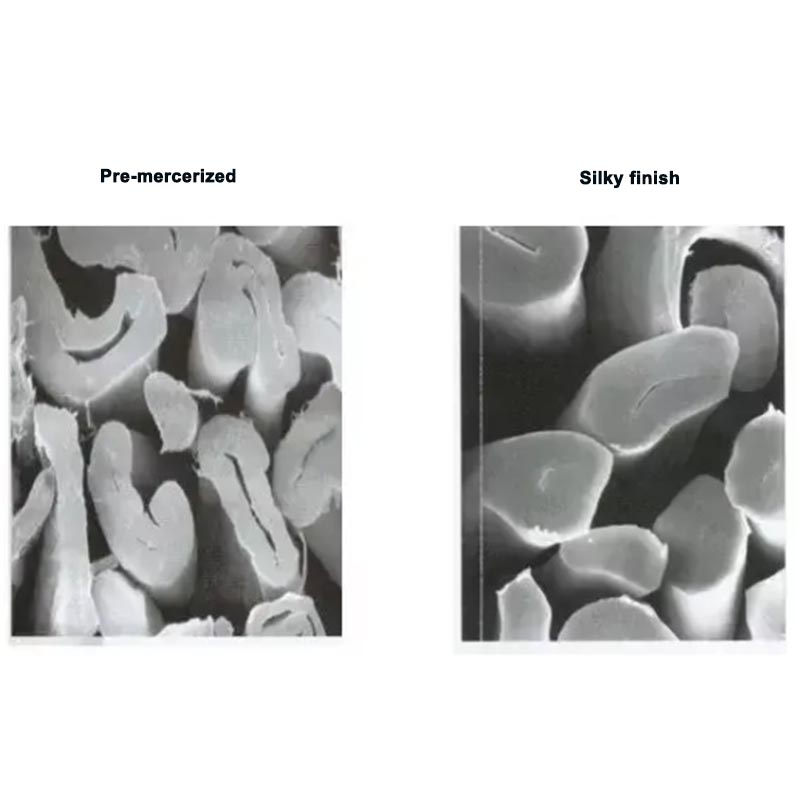

5. Mercerized (lesela la k'hothone)

Lesela tlas'a boemo bo itseng ba tsitsipano, ka thuso ea concentrated caustic soda le ho boloka boholo bo hlokahalang, bo ka fumana khanya ea silky, mokhoa ona o bitsoa mercerization.

(1) Morero oa mercerization:

A. Ntlafatsa khanya ea holim'a metsi le ho ikutloa ha lesela, ka lebaka la ho ruruha ha fiber, tokisetso ea fiber e hlophisehile haholoanyane, 'me ho bonahatsa leseli ho tloaelehile, kahoo ho ntlafatsa khanya.

B.Eketsa sekhahla sa 'mala oa ho daea ka mor'a ho qeta mercerizing, sebaka sa fiber se fokotseha, sebaka sa amorphous se eketseha,' me dae e ka 'na ea kena ka har'a likhoele, tekanyo ea mebala ho feta fiber ea k'hothone ea mercerized e eketsehile ka 20%, le bokhabane bo ntlafala, ka nako e tšoanang eketsa matla a ho koahela ka pele.

C. Ho ntlafatsa botsitso ba dimensional mercerizing e phethetse phello ea moralo, e ka felisa makukuno a thapo, e ka fihlela litlhoko tsa boleng ba ho daea le ho hatisa lihlahisoa tsa halofo le halofo. Ntho ea bohlokoa ka ho fetisisa ke hore ka mor'a mercerizing, botsitso ba deformation ea ho atolosa lesela bo ntlafalitsoe haholo, kahoo ho fokotsa haholo tekanyo ea ho fokotseha ha lesela.

6. Ho hloekisa, ho fokotseha pele (lesela la fiber ea lik'hemik'hale)

Sepheo sa ho hloekisa pele ho fokotseha ke haholo-holo ho tlosa oli, slurry le litšila tse adsorbated holim'a lesela (fiber) nakong ea ho loha polokelo le lipalangoang, 'me ka nako e ts'oanang, li-oligomers tse ling holim'a fiber li ka boela tsa qhibiliha ka mocheso o phahameng oa ho hloekisa. Lesela le bohlooho le lokela ho ba pele ho ho fokotseha pele ho palo ea alkali, 'me li-additives tse kang olein le caustic soda li lokela ho kenngoa haholo-holo. Phekolo ea pele ea lesela la fiber ea lik'hemik'hale e etsoa ka mocheso o phahameng le mochine o daeang khatello e phahameng.

7.Ho fokotseha ha alkali (lesela la fiber ea lik'hemik'hale)

(1) Molao-motheo le phello ea ho fokotsa alkali

Kalafo ea phokotso ea alkali ke mokhoa oa ho phekola lesela la polyester ka mocheso o phahameng le li-lye tse tukang. Polyester fiber e entsoe ka hydrolyzed mme e robehile ke ester bond ea polyester molecular chain ka holim'a fiber ka sodium hydroxide aqueous solution, 'me lihlahisoa tsa hydrolysis tse nang le likhato tse fapaneng tsa polymerization li tsoela pele ho thehoa,' me qetellong ho thehoa ha sodium terephthalate le ethylene glycol. Thepa e fokotsang alkali haholo-holo e kenyelletsa mochini o daeang o khaphatsehang, mochini o tsoelang pele o fokotsang, mochini o fokotsang nako le nako oa mefuta e meraro, ntle le mochini o daeang o khaphatsehang; Mechini e sa khaotseng le ea nakoana e fokotsang e ka sebelisa li-lye tse setseng. E le ho etsa bonnete ba botsitso ba sebopeho sa ponahalo le boholo ba lesela le bohlooho bakeng sa lihlahisoa tse ling tsa ho fokotsa alkali, ho hlokahala ho eketsa ts'ebetso e reriloeng esale pele, ebe o kenya mokhoa oa ho daea.

Nako ea poso: Feb-28-2025